The Mechanical Joint Integrity (MJI) model was originally developed by ECITB in 2011 with industry experts to address a need to resolve hydrocarbon release issues experienced in North Sea operations. This model of training has since been adopted by many UK oil and gas operators and contracting companies.

The MJI model is intended to reflect “good practice” for the training and competence of workers in relation to mechanical joint operations, both on and offshore. Primarily aimed at those workers required to undertake mechanical jointing tasks. The model is also relevant for planners and supervisors of such operations.

The MJI model comprises a four stage model of training and competence that can be used by both new entrants and experienced workers involved in mechanical joint operations. Each stage is outlined below:

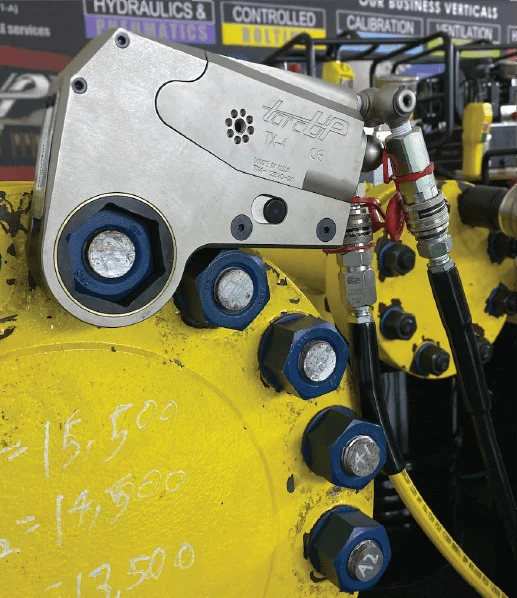

The support the MJI trainer provides to a learner throughout the MJI training course is of critical importance, therefore to ensure high quality instruction and the safety of learners whilst using hand and hydraulic equipment in MJI courses, a maximum ratio of 1 trainer to 6 learners is the requirement.

A new or relatively inexperienced worker will attend an ECITB approved training to gain knowledge, skills and practice on mechanical joint operations. The training will normally take place onshore and consist of classroom and workshop learning activities. The courses are normally from 1 to 2.5 days depending upon the subject matter.

Some courses from approved providers may be delivered in a blended learning format where the theory is covered by e-learning or virtual classroom with the learner attending the training provider’s premises to take the knowledge test and practical training.

Each person will be taught theoretical and practical skills in the relevant subject matter to a technical training standard specified by the ECITB, which is then followed by a knowledge test and practical exercises.

Each new worker, after attending an approved course and gaining a training certificate, requires a period of workplace experience to practise new skills and knowledge. This will allow consolidation of skills and knowledge through work based tasks. The learner will be given a Work Based Task Assignment (pic 2), specifying a range of tasks and complex jobs to be completed before they can move on to Stage 3 (Technical Testing). The Work Based Task Assignment will typically take between 3 and 12 months to complete. The learner must satisfactorily demonstrate that they have carried out each of the steps indicated in the Work Based Task Assignment on a minimum of three occasions.

The Work Based Task Assignment record may be verified by any person with overall responsibility for the safe, correct and accurate completion of the bolting task. This could be:

• A supervisor or team leader holding MJI certification

• A line manager holding MJI certification.

The Training Provider will issue the relevant Work Based Task Assignments to each learner at the end of each approved training course and explain its purpose and use.

Stage 3 requires each individual to complete a formal assessment of their job knowledge, skills and ability in each Mechanical Joint Integrity subject. The ECITB technical competence validation tests comprise two elements – knowledge testing and practical skills testing:

The candidate will undertake a highly specified practical assessment with candidate instructions in various prescribed stages under continuous observation by an examiner. All parts of the practical test must be completed to the required standard; the candidate will be given access to reference materials for the practical element of the test. All test criteria must be met to achieve a pass. Any test criteria not achieved to the specified standard will result in a requirement to re-sit the test after 4 weeks.

Successful personnel will be awarded an ECITB Certificate of Achievement (pic 3) at Stage 3 Testing and Stage 4 Re-testing. The certificate is valid for three years.

To confirm the individual’s current skills, knowledge and ability, the ECITB Technical Competence Validation Test is undertaken every 3 years to prove continued skill levels. If required, the individual can undertake a short computer based training module to refresh their theory knowledge before attempting the technical test. A number of approved MJI providers can offer computer based modules taking 2 to 5 hours in the following subjects: